What’s the requirments of EN20471?

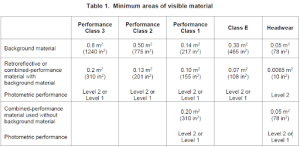

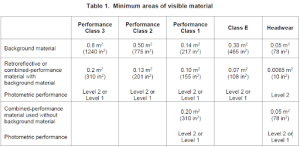

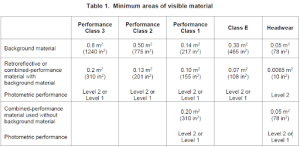

- Requirement of visible material

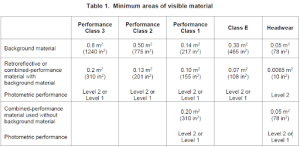

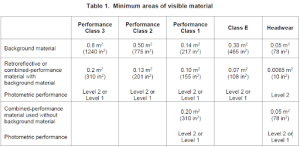

Table 1 – Minimum required areas of visible material in m²

The initial retro reflection coefficient for separate performance retro reflective materials shall exceed 330 cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for combined performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For all kinds of garments, the background material shall encircle the torso and trouser legs and shall maintain a minimum width(height) of 50 mm. Interruptions by retro reflective stripes are not counted. Bands of retro reflective material shall be at least 50 mm wide. The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart.

2) For garments covering the torso and arms, if a sleeve blocks a clear view of a horizontal band on the torso, then the sleeve should be surrounded by a reflective band. If a sleeve blocks a clear view of two horizontal bands on the torso, then the sleeve must be surrounded by two reflective bands with at least 50 mm from each other, with the lower band at least 50 mm from the end of the sleeve.

3) Harnesses are excluded from the scope of the new standard and cannot be certified as meeting EN ISO 20471:2013.

4) A class 2 jacket and a class 2 pair of trousers might be combined and certified as a class 3 ensemble.

What’s the requirments of ANSI/ISEA 107?

- Requirement of visible material

The initial retro reflection coefficient for Level 2 retro reflective or combined-performance material shall exceed 330cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for Level 1 retro reflective or combined-performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For Performance Class 3, the retroreflective or combined performance material incorporated into the garment shall not be less than 50 mm. For Performance Class 2, the width shall not be less than 35 mm. And for Performance Class 1, the width shall not be less than 25 mm; but if there is no background material, then the width of combined-performance material shall not be less than 50 mm.

2) The spacing between multiple bands shall be at least equal to the band width.

3) The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart. Interruptions by retro reflective stripes are not counted.

What’s the requirments of ANSI/ISEA 107?

- Requirement of visible material

The initial retro reflection coefficient for Level 2 retro reflective or combined-performance material shall exceed 330cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for Level 1 retro reflective or combined-performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For Performance Class 3, the retroreflective or combined performance material incorporated into the garment shall not be less than 50 mm. For Performance Class 2, the width shall not be less than 35 mm. And for Performance Class 1, the width shall not be less than 25 mm; but if there is no background material, then the width of combined-performance material shall not be less than 50 mm.

2) The spacing between multiple bands shall be at least equal to the band width.

3) The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart. Interruptions by retro reflective stripes are not counted.

What’s the requirments of ANSI/ISEA 107?

- Requirement of visible material

The initial retro reflection coefficient for Level 2 retro reflective or combined-performance material shall exceed 330cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for Level 1 retro reflective or combined-performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For Performance Class 3, the retroreflective or combined performance material incorporated into the garment shall not be less than 50 mm. For Performance Class 2, the width shall not be less than 35 mm. And for Performance Class 1, the width shall not be less than 25 mm; but if there is no background material, then the width of combined-performance material shall not be less than 50 mm.

2) The spacing between multiple bands shall be at least equal to the band width.

3) The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart. Interruptions by retro reflective stripes are not counted.

What’s the requirments of ANSI/ISEA 107?

- Requirement of visible material

The initial retro reflection coefficient for Level 2 retro reflective or combined-performance material shall exceed 330cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for Level 1 retro reflective or combined-performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For Performance Class 3, the retroreflective or combined performance material incorporated into the garment shall not be less than 50 mm. For Performance Class 2, the width shall not be less than 35 mm. And for Performance Class 1, the width shall not be less than 25 mm; but if there is no background material, then the width of combined-performance material shall not be less than 50 mm.

2) The spacing between multiple bands shall be at least equal to the band width.

3) The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart. Interruptions by retro reflective stripes are not counted.

What’s the requirments of ANSI/ISEA 107?

- Requirement of visible material

The initial retro reflection coefficient for Level 2 retro reflective or combined-performance material shall exceed 330cd/(lx • m²) at observation angle 12° and entrance angle 5°; while the initial retro reflection coefficient for Level 1 retro reflective or combined-performance material shall exceed 65 cd/(lx ∙ m²).

- Garment Design

1) For Performance Class 3, the retroreflective or combined performance material incorporated into the garment shall not be less than 50 mm. For Performance Class 2, the width shall not be less than 35 mm. And for Performance Class 1, the width shall not be less than 25 mm; but if there is no background material, then the width of combined-performance material shall not be less than 50 mm.

2) The spacing between multiple bands shall be at least equal to the band width.

3) The bottom of the lowest torso band shall be at least 50 mm above the bottom edge. If more than one horizontal band is applied, the horizontal bands shall be at least 50 mm apart. Interruptions by retro reflective stripes are not counted.

What’s the requirments of industry standards?

Below is the list and brief introduction of commonly used international Standards in this industry. For more detailed information, please contact our customer service team.

High Visibility Clothing For Professional Use

EN ISO 20471:2013

European standard for high visibility clothing & accessories

The International Organization for Standardization released on 28th June 2013 the new EN ISO 20471:2013 standard for the test methods and requirements of high visibility clothing. All EEC Type Examination Certificates based on EN 471 for high visibility clothing became invalid on 1st October 2013 regardless of any other mentioned validity date. Requirements are included for color, retro reflection and Physiological performance as well as for the minimum areas of visible material in high visibility clothing.

EN 20471 imposes requirements on visible workwear for employees in high-risk areas. The employees will be visible and safe at night, during the day, and from all angles. There are three classes which are related to risk assessment and are defined by the minimum areas of background fluorescent and retro-reflective material.

CLASS 1 performance provides less visibility than Class 2 or 3, but can be a good alternative for low risk duties and environments. It requires a minimum of 0.14m² of background material and 0.10m² of retro reflective material.

CLASS 2 performance is of intermediate level, requires a minimum of 0.50m² of background material and 0.13m² of retro reflective material.

CLASS 3 performance provide the highest level of conspicuity. A Class 3 garment is required to cover the torso and have sleeves with reflective bands or/and trouser legs with reflective bands. It requires a minimum of 0.80m² of background material and 0.20m² of retro material.

To get more detailed information on requirements of EN ISO 20471, please contact our service staff or send us emails.

ANSI/ISEA 107-2020

American national standard for high-visibility safety apparel and accessories

ANSI/ISEA 107-2020 is the American National Standard for High-Visibility Safety Apparel and Headwear. This standard provides an authoritative guide for the design, color, photometric and physical performance, use and test methods of high-visibility safety apparel including safety vests, hi vis jackets, bib coveralls, pants and harnesses. Based on different work environment, the standard classified the performance into three classes.

ANSI 107-2020 standard includes a “Type” structure that keeps off-road (“Type O”), roadway (“Type R”), and public safety (“Type P”) garments separate by application and work environment. The types are further broken down into classes 1, 2 or 3. Three classes help the user to choose the proper garments based on expected work environment risks.

TYPE O, CLASS 1 garments provides the minimum visibility to differentiate the wear from non-complex work environments where struck-by hazards will not be approaching at roadway speeds. It requires a minimum of 217 in² of background material and 155 in² of retro reflective or combined performance material.

TYPE R (Roadway use) garments are for occupational workers who are exposed to roadway traffic and who work in an environment with moving equipment/vehicles.

TYPE R, CLASS 2 garment is of intermediate level, for workers who will be exposed to traffic with speeds in excess of 25 mph. It requires a minimum of 775 in²(smallest size 540 in²) of background material and 201 in² of retro reflective or combined performance material.

TYPE R, CLASS 3 garments provide the highest level of safety, for workers who will be exposed to high speed traffic or reduced sight distances. It requires a minimum of 1240 in²(smallest size 1000 in²) of background material and 310 in² of retro reflective or combined performance material.

TYPE P CLASS 2 garments provides additional options for emergency responders, incident responders and law enforcement in temporary traffic control (TTC) zones. It requires a minimum of 450 in² of background material and 201 in² of retro reflective or combined performance material.

CLASS E as a supplement type of ANSI 107, can be applied to rain pants, bib pants, shorts etc. It can Combine with a Class 2 vest for an ANSI Class 3 ensemble; or a Class 3 vest to attain a higher level visibility. It requires a minimum of 465 in² of background material and 109 in² of retro reflective or combined performance material.

Can black high visibility clothing be ANSI compliant as well?

If a hi vis vest has background material that is completely black, without the inclusion of any fluorescent material, it does not meet the standard for ANSI compliance.

For a high visibility vest to meet the ANSI standard it must include a background material in either fluorescent yellow-green, fluorescent orange-red, or fluorescent red.

Black High Visibility Gear can be compliant as long as the vest includes a sufficient surface area of the required fluorescent background material, the rest of the vest can be composed of black material if desired.

To get more detailed information on guidance provided by ANSI/ISEA 107-2010, please contact our service staff or send us emails.

AS/NZS 1906.4-2010

Retroreflective materials and devices for road traffic control purposes

AS/NZS 1906.4:2010 is the joint Australian/New Zealand Standard for retro reflective materials and devices for road traffic control purposes. It specifies the photometric, colorimetric and physical property requirements for high-visibility materials to be used in high visibility safety clothing, rather than the clothing themselves. The design requirements for high-visibility clothing are specified in AS/NZS 4602.1. For more detailed information, you’re welcomed to consult our service staff online or by email.

AS/NZS 4602.1:2011

Australia / New Zealand standard for high visibility safety garments

AS/NZS 4602.1 specifies the visual requirements for high visibility garments to ensure appropriate visibility for workers who may be exposed to traffic hazard in high risk situations. It also refers to another standard AS/NZS 1906.4:2010 for the reflective material that are used in the garments. There are three classes relating to the application of the garments. Class D for daytime use only, Class N for nighttime use only, and Class D/N for day and/or night time use.

CLASS D garments made from fluorescent or other high visibility background materials without retro-reflective tape, are designed for daytime use only. The minimum area of high visibility background material shall be no less than 0.2 m² both front and back.

CLASS N garments are intended to provide the wearer with high visibility at night when illuminated by light, such as car headlight. It is manufactured with retro-reflective strips on a background fabric and are designed to make the wearer visible from all angles.

CLASS D/N garments combine fluorescent or other high visibility background materials with retro reflective tape, making them suitable for day and night use, or for workplace with low light conditions. Retro-reflective tape shall comply to AS/NZS 1906 and in specific tape configurations.

CAN/CSA Z96-15

Canadian standard for high visibility safety apparel

CAN/CSA Z96-15 describes the requirements for high visibility apparel for Canadian workers to be seen by vehicle operators, especially in low-light conditions or darkness. CSA lists three classes of garments based on body coverage provided.

CLASS 2 apparel has full coverage of the upper torso(front, back, sides and over the shoulders). Stripes/bands shall be composed of retro-reflective or combined performance materials, and are to be displayed to ensure 360°visibility.

CLASS 3 apparel provides the greatest body coverage and visibility. Apparel meets the same requirements as Class 2 with the addition of bands around both arms and legs.

FAQs About Products

Reflective Fabric Tape

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for reflective fabric?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for reflective fabric?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 5-15 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

7. Are the reflective fabrics AZO-free?

Yes. We update our OEKO-TEX 100 and REACH certificates annually to make sure our reflective fabrics are AZO-free.

8. Are the reflective fabric poisonous metal free?

Yes. We have REACH report to proof that our reflective fabric is poisonous metal free.

9. In case we want different widths of reflective fabric, can you cut it for us?

Yes. The full width of reflective fabric is around 140cm. We provide free cutting according to customers’ requirements.

10. What certificates do you have?

Our products are certified by SATRA, CALCOAST, AWTA, TEXTEST, UL, SGS to meet the requirements of EN20471, ANSI107:2015, CSA-Z96, AS NZS 1906, EN 469, NFPA 701, NFPA 2112, NFPA 1971, EN 14116, ASTM F 1506 etc.

11. Can we print our company logo on the reflective fabric?

Yes. We can do customized printing on the surface or back side of the reflective fabric.

12. Is reflective fabric washable?

Yes. Our reflective fabric is washable. Washing cycles of different products varies from 5 to over 100 times to meet different customers’ requirements. We also have reflective fabric that can endure industrial wash and dry cleaning.

13. How do you define the washing cycles?

It means that after being washed for certain cycles according to international washing standards (ISO 6330 for home wash, ISO 3175 for dry cleaning and ISO 15797 for industrial wash), the reflective value is higher than 100 cd/(lux•m²) (measured from angle 5°12′).

14. What are the main requirements of EN20471 and ANSI 107 toward reflective fabric?

Requirements for reflective fabric mainly include reflective coefficient, physiological and washing performance.

1) When measured on new product at 5.0° entrance and 0.2°observation angles, reflective coefficient shall be greater than 330 cd/lx.m².

2) After exposure test like abrasion, flexing, folding at cold temperatures, rainfall etc. the retro reflection coefficient shall be greater than 100 cd/lx.m².

3) After at least 25 washes, the reflective coefficient shall be larger than 100 cd/lx.m².

15. If we want to change the base fabric of reflective fabric, can you customize for us? And what’s the MOQ for that?

Yes. We’ll test the base fabric see if it’s suitable for coating. If the test results is ok. We can customize for you and the MOQ is 500 square meters.

Photoluminescent Materials

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for photoluminescent materils?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

5. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

6. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

- What is your classification about your products?

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development it is now considered necessary to extend the PSPA material classification systems as follows:

| Luminance mcd/m2 | 2mins | 10mins | 30mins | 60mins |

| Class A | 108 | 25 | 7 | 3 |

| Class B | 210 | 50 | 15 | 7 |

| Class C | 690 | 140 | 45 | 20 |

| Class D | 1100 | 260 | 85 | 35 |

| Class E | 1800 | 400 | 120 | 55 |

| Class F | 2300 | 520 | 155 | 70 |

| Class G | 3000 | 650 | 190 | 80 |

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398(also ISO 16069)

Illuminated with 1000 lux from Xenon D75(Daylight) source for 5 minutes(very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illuminaton and time.

7. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

Photoluminescent Materials

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for photoluminescent materils?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

5. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

6. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

- What is your classification about your products?

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development it is now considered necessary to extend the PSPA material classification systems as follows:

| Luminance mcd/m2 | 2mins | 10mins | 30mins | 60mins |

| Class A | 108 | 25 | 7 | 3 |

| Class B | 210 | 50 | 15 | 7 |

| Class C | 690 | 140 | 45 | 20 |

| Class D | 1100 | 260 | 85 | 35 |

| Class E | 1800 | 400 | 120 | 55 |

| Class F | 2300 | 520 | 155 | 70 |

| Class G | 3000 | 650 | 190 | 80 |

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398(also ISO 16069)

Illuminated with 1000 lux from Xenon D75(Daylight) source for 5 minutes(very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illuminaton and time.

7. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

Photoluminescent Materials

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for photoluminescent materils?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

5. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

6. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

- What is your classification about your products?

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development it is now considered necessary to extend the PSPA material classification systems as follows:

| Luminance mcd/m2 | 2mins | 10mins | 30mins | 60mins |

| Class A | 108 | 25 | 7 | 3 |

| Class B | 210 | 50 | 15 | 7 |

| Class C | 690 | 140 | 45 | 20 |

| Class D | 1100 | 260 | 85 | 35 |

| Class E | 1800 | 400 | 120 | 55 |

| Class F | 2300 | 520 | 155 | 70 |

| Class G | 3000 | 650 | 190 | 80 |

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398(also ISO 16069)

Illuminated with 1000 lux from Xenon D75(Daylight) source for 5 minutes(very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illuminaton and time.

7. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

Photoluminescent Materials

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for photoluminescent materils?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

5. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

6. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

- What is your classification about your products?

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development it is now considered necessary to extend the PSPA material classification systems as follows:

| Luminance mcd/m2 | 2mins | 10mins | 30mins | 60mins |

| Class A | 108 | 25 | 7 | 3 |

| Class B | 210 | 50 | 15 | 7 |

| Class C | 690 | 140 | 45 | 20 |

| Class D | 1100 | 260 | 85 | 35 |

| Class E | 1800 | 400 | 120 | 55 |

| Class F | 2300 | 520 | 155 | 70 |

| Class G | 3000 | 650 | 190 | 80 |

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398(also ISO 16069)

Illuminated with 1000 lux from Xenon D75(Daylight) source for 5 minutes(very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illuminaton and time.

7. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

Photoluminescent Materials

1. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

2. Do you keep stocks for photoluminescent materils?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

3. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

4. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

5. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

6. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

- What is your classification about your products?

With recent developments in Codes and Standards for Photoluminescent Safety Products and in line with the recognized industry development it is now considered necessary to extend the PSPA material classification systems as follows:

| Luminance mcd/m2 | 2mins | 10mins | 30mins | 60mins |

| Class A | 108 | 25 | 7 | 3 |

| Class B | 210 | 50 | 15 | 7 |

| Class C | 690 | 140 | 45 | 20 |

| Class D | 1100 | 260 | 85 | 35 |

| Class E | 1800 | 400 | 120 | 55 |

| Class F | 2300 | 520 | 155 | 70 |

| Class G | 3000 | 650 | 190 | 80 |

The PSPA classification system is based on luminance decay data as given when tested according to ISO 17398(also ISO 16069)

Illuminated with 1000 lux from Xenon D75(Daylight) source for 5 minutes(very similar to DIN 67510 Part 1 and ASTM E 2073-10 also with this illuminaton and time.

7. Could you customized products according to my requirment?

Yes. We provide customization service for all of our photoluminescent products.For photoluminescent pigment, we can customize glow color, apparent color, grain size, water resistance and afterglow intensity for you. For photoluminescent film and photoluminescent rigid sheet, we can customize its afterglow intensity, glow color, apparent color, shapes, patterns, whether it comes with a protective layer or bottom layer.

Most of our photoluminescent signs are custom made, We also have patterns available which customers can purchase directly. We have designed and manufactured multiple high standard glow in the dark signs for our clients including UL certificated signs and IMO standard signs and tapes.

To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.

Personal Protective Equipment

-

What is PPE?

You’ve heard them PPE, but really what does it all mean and how fast is the landscape? PPE manufacturers and distributors are a designated part of the Essential Critical Infrastructure Workforce. PPE includes the crucial gear and equipment needed to conduct a range of operations and services to keep workers safe across a wide variety of industries and applications. Learn more directly from Highviz Industrial.

2. Can we get free samples?

Yes. We can provide certain quantity of free samples for review, please feel free to contact us.

3. Do you keep stocks for PPE?

Yes. We keep stocks for regular products and can be sent out immediately. Please feel free to contact us for more details.

4.What about customizing your PPE

4. What’s the regular leading time for photoluminescent materils?

We keep stock for regular products which can be sent out immediately. For non stock products, our leading time is usually around 20-30 days depending on the products and quantity.

5. Do you accept small order or quantity less than MOQ?

Yes. We keep stock for regular products. For stock products, we can accept small order. For non-stock products, please contact our sales to see if we can lower the MOQ for you.

6. What certificates do you have?

Our products with reach REACH certification. Rohs, ASTM and SHVC test reports for not containing harmful or heavy metal elements.Photoluminescent film has DIN-GL, DNV, IMO, Rohs test reports for not containing harmful or heavy metal elements, flame retardant and being allowed to use as LLL.

7.What about customizing your PPE?

Custom safety glasses, custon work gloves, custom safety vest with logo. Logo’d safety gear, turn to Highviz Industrial to get your PPE customized whenever possible. Expand your brand or message by adding your logo to glasses or vests, or messages on gloves. To start your customization, please contact our representative with more details, like the specification you are looking for and how much you will need.